We are providers of industrial solutions, certified as GOLD System Integrators by Rockwell Automation, specializing in control, process, energy, and machine safety solutions.

Our comprehensive plant-wide vision and expertise in industrial automation, combined with Rockwell Automation's global capabilities and extensive experience, give our customers a competitive edge in optimizing industrial systems to deliver even greater value and superior results

Nuestra visión de planta integral y nuestra experiencia en automatización industrial, combinadas con las capacidades mundiales y la amplia experiencia de Rockwell Automation, proporcionan a nuestros clientes una ventaja competitiva en la optimización de sistemas industriales para ofrecer aún más valor y resultados superiores.

We are providers of industrial solutions, certified as GOLD System Integrators by Rockwell Automation, specializing in control, process, energy, and machine safety solutions.

Our comprehensive plant-wide vision and expertise in industrial automation, combined with Rockwell Automation's global capabilities and extensive experience, give our customers a competitive edge in optimizing industrial systems to deliver even greater value and superior results

We are an industrial solutions provider, certified as a Rockwell Automation GOLD System Integrator in control, process, power, and safety.

Our plantwide vision, and proficiency in industrial automation, coupled with Rockwell Automation's worldwide capabilities and extensive experience, provides our clients with a competitive advantage in optimizing industrial systems to bring even more value and higher outcomes.

Somos proveedores de soluciones industriales, estamos certificados como Integradores de Sistemas GOLD de Rockwell Automation especialistas en soluciones de control, proceso, energía y seguridad de máquina.

Nuestra visión de planta integral y nuestra experiencia en automatización industrial, combinadas con las capacidades mundiales y la amplia experiencia de Rockwell Automation, proporcionan a nuestros clientes una ventaja competitiva en la optimización de sistemas industriales para ofrecer aún más valor y resultados superiores.

SOFTWARE ENGINEERING | FIELD SERVICES

PLC, HMI and Scada system programming

Allen Bradley, Siemens, Schneider, ABB, Keyence, Mitsubishi, Delta

Development of applications

HMI & Scada

Development of cross-platform applications

Ignition software

PLC Care

Ensures the continuity of your operations and existing systems with unique expertise in end-of-life PLCs and HMIs. Backup, on-site service and connect new equipment to your existing system

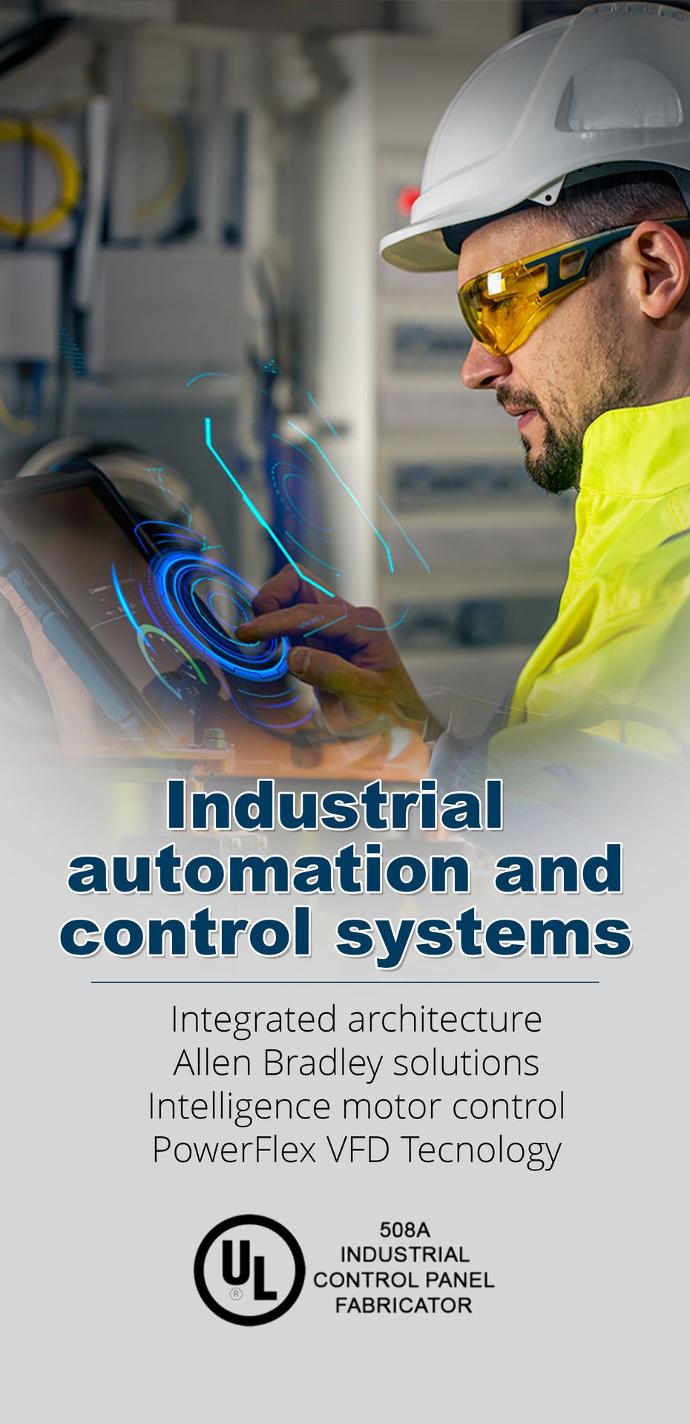

HARDWARE ENGINEERING

Electrical diagrams

General electrical schematic drawings, component wiring diagramsSO

UL508A designs

UL 508A certified panel shop with in-house electrical engineering capabilities and designers that are experienced in drafting, building, programming, and supporting control panels

Communication networks

We provide a holistic approach to help you design, deploy, and manage your network infrastructure

Control systems and I/O

Control and safety solutions built with controllers and I/O at its core

SOFTWARE ENGINEERING | FIELD SERVICES

PLC, HMI and Scada system programming

Allen Bradley, Siemens, Schneider, ABB, Keyence, Mitsubishi, Delta

Development of applications

HMI & Scada

Development of cross-platform applications

Ignition software

PLC Care

Ensures the continuity of your operations and existing systems with unique expertise in end-of-life PLCs and HMIs. Backup, on-site service and connect new equipment to your existing system

HARDWARE ENGINEERING

Electrical diagrams

General electrical schematic drawings, component wiring diagramsSO

UL508A designs

UL 508A certified panel shop with in-house electrical engineering capabilities and designers that are experienced in drafting, building, programming, and supporting control panels

Communication networks

We provide a holistic approach to help you design, deploy, and manage your network infrastructure

Control systems and I/O

Control and safety solutions built with controllers and I/O at its core

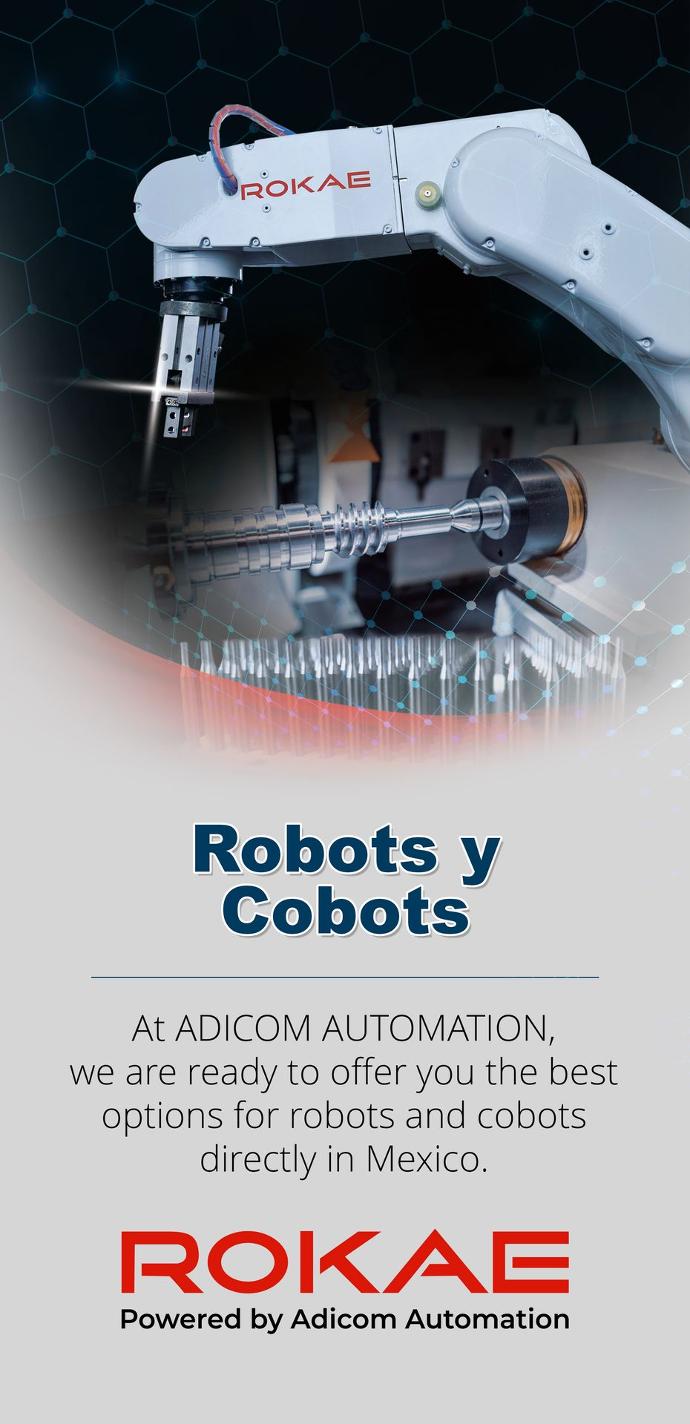

ROKAE IN MÉXICO

Adicom Automation introduces the most advanced and cutting-edge robotic technology to Mexico by presenting the new generation of robotic systems. We offer intelligent solutions designed to meet the needs of various industries, such as automotive parts, 3C technology, high-precision processing, medical, and more. We specialize in lightweight and collaborative robots with an IP67 rating.

ROKAE IN MÉXICO

Adicom Automation introduces the most advanced and cutting-edge robotic technology to Mexico by presenting the new generation of robotic systems. We offer intelligent solutions designed to meet the needs of various industries, such as automotive parts, 3C technology, high-precision processing, medical, and more. We specialize in lightweight and collaborative robots with an IP67 rating.

Industries

Coffee production line control: Implemented 20 control panels featuring NEMA 4X protection, 316 stainless steel construction, and integration with Allen Bradley's FLEX I/O remote node. Additionally, the system includes a FESTO brand valve control manifold.

Stator line modernization with process units: Enhancing efficiency in varnishing, preheating, second varnishing, horizontal oven-type warehousing, painting, drying, and electrical testing of the product.

.

Press control system modernization: Enhancing operational efficiency (OEE or ETE) for a globally recognized electrical appliance manufacturing company. This initiative aims to reduce stoppages caused by flywheel motorization failures, including the installation of power and control channeling.

We successfully implemented a Motor Control Center (MCC) with Danfoss variable frequency drives, achieving energy consumption optimization.

In the sugar industry, where energy demand can be substantial, this has translated into significant savings.

The implementation of the recommended filters on a marine platform resulted in a significant improvement in power quality. Harmonic levels and voltage fluctuations were dramatically reduced, optimizing the stability of the electrical system.

Industrias

Coffee production line control: Implemented 20 control panels featuring NEMA 4X protection, 316 stainless steel construction, and integration with Allen Bradley's FLEX I/O remote node. Additionally, the system includes a FESTO brand valve control manifold.

Stator line modernization with process units: Enhancing efficiency in varnishing, preheating, second varnishing, horizontal oven-type warehousing, painting, drying, and electrical testing of the product.

Press control system modernization: Enhancing operational efficiency (OEE or ETE) for a globally recognized electrical appliance manufacturing company. This initiative aims to reduce stoppages caused by flywheel motorization failures, including the installation of power and control channeling.

We successfully implemented a Motor Control Center (MCC) with Danfoss variable frequency drives, achieving energy consumption optimization.

In the sugar industry, where energy demand can be substantial, this has translated into significant savings.

The implementation of the recommended filters on a marine platform resulted in a significant improvement in power quality. Harmonic levels and voltage fluctuations were dramatically reduced, optimizing the stability of the electrical system.

Experts in Rockwell Automation technology

Delivering cutting-edge solutions for optimized operations across the plant

Control

Customizable panels designed for a variety of industries, speeding up time-to-market and lowering costs in designing, developing, and delivering machines.

LV drive system

Our industry expertise enables us to deliver comprehensive drive solutions that maximize production and minimize risk.

Experts in Rockwell Automation technology

Delivering cutting-edge solutions for optimized operations across the plant

Control

Customizable panels designed for a variety of industries, speeding up time-to-market and lowering costs in designing, developing, and delivering machines.

LV drive system

Our industry expertise enables us to deliver comprehensive drive solutions that maximize production and minimize risk.

Trusted by 20+ recognized companies across the country